Laser Peening Explained in Five Minutes

What is Laser Peening?

Posted: May 29, 2018

By:

Laser peening is a surface enhancement method for improving metal fatigue strength and damage tolerance by inhibiting crack growth. The process is often called Laser Shock Peening (LSP) because it uses a powerful shockwave to plastically deform the metal and produce compressive residual stress.

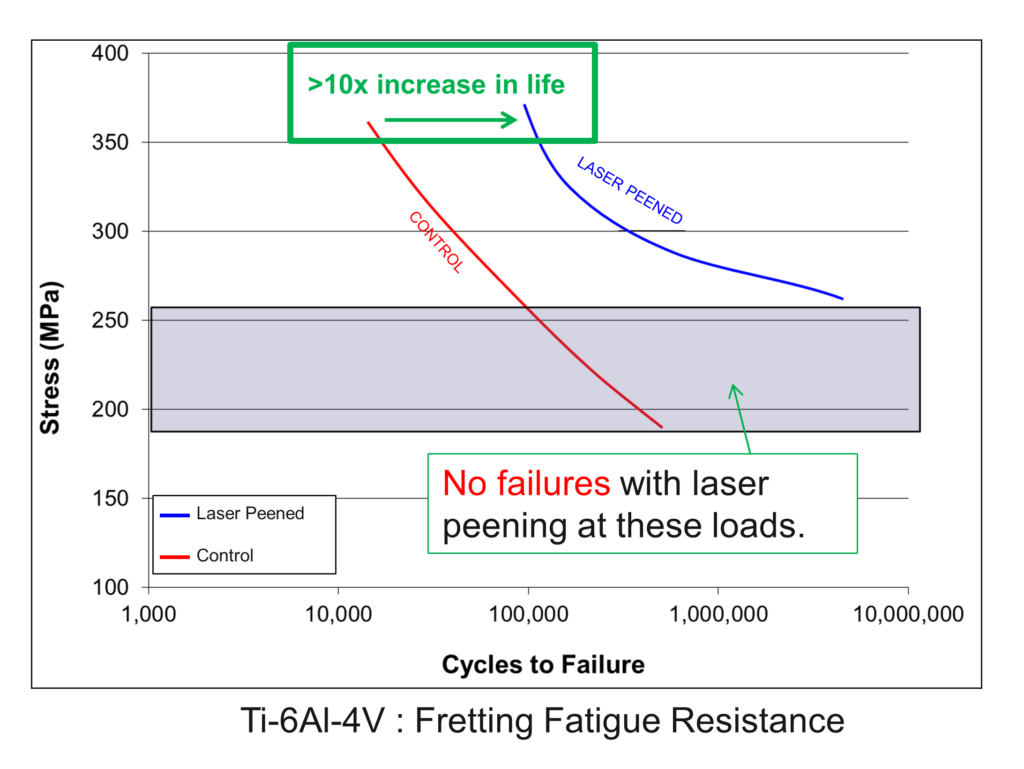

In principle, laser peening is similar to shot peening, but it produces deeper and stronger compressive stress. This difference can be great – 10X deeper or more for laser peened components. As a result, laser peened parts can last 10X longer as crack propagation is slowed or halted altogether.

How Does Laser Peening Work?

Here’s a step-by-step breakdown of the laser peening process:

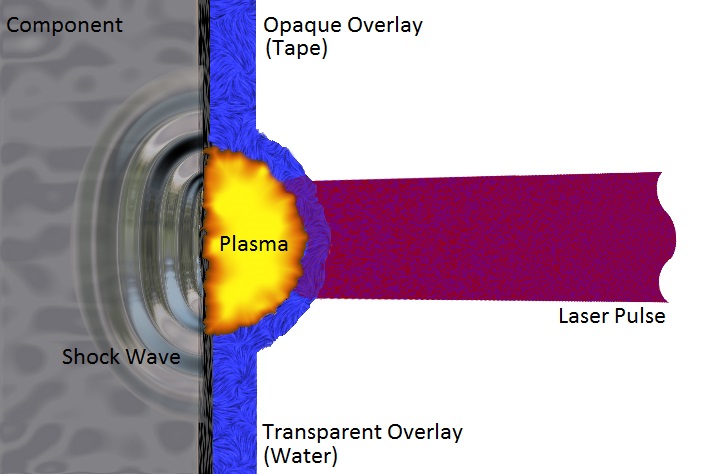

- A high-energy laser pulse is directed at the target.

- The concentrated laser energy generates a high-pressure expanding plasma on the metal surface.

- The plasma expansion is confined by water flowing over the treatment area.

- The rapid pressure rise from the confined plasma shocks the surface, sending a powerful shockwave into the material.

- The shockwave produces localized plastic deformation in the metal.

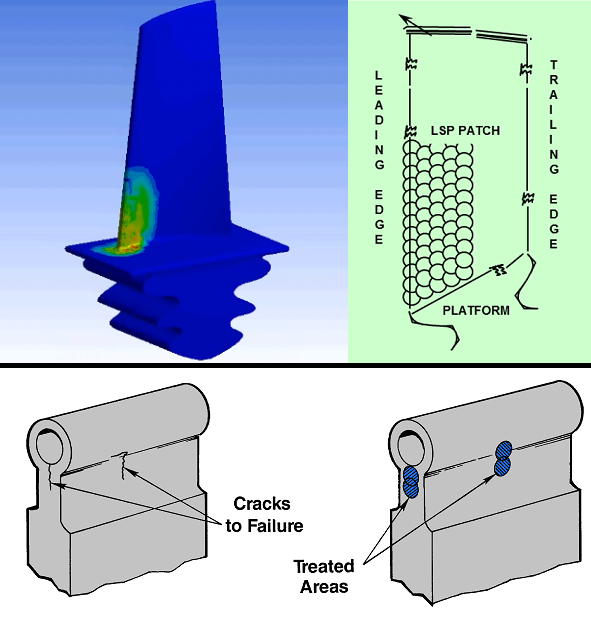

- This sequence is repeated in a strategic pattern over the processing area resulting in a robust layer of compressive residual stress.

Why Laser Peen?

Compressive residual stresses are crucial for inhibiting crack growth and extending component life. Compressive stress offsets the tensile stress that generates fatigue cracks, and it slows the propagation of crack tips once they form. Deeper compressive stresses provide superior protection, inhibiting subsurface cracks that could lead to sudden component failure.

Laser peening was first adopted by aerospace manufacturers to protect high-value components like engine blades and landing gear. Laser peening has since spread to other industries, demonstrating benefits in automotive and heavy equipment manufacturing, medical implant durability, life extension for tooling and dies, and power generation infrastructure. Realistically, laser peening can be used to improve the strength and durability of virtually any metal component. It works on all metals and can be tailored to impart predictable strain gradients at precise locations on a component.

Who is LSP Technologies?

LSP Technologies (LSPT) was founded in 1995 as the world’s first commercial laser peening provider. The company performs laser peening production services out of Dublin, Ohio, enhancing high-value components for manufacturers from a variety of industries.

LSPT is the only company in the world selling commercial laser peening equipment. The Procudo® Laser Peening System is engineered for high-volume production processing and can be integrated directly into the manufacturing line.

Contact LSPT to learn more.

Interested in Seeing More?

Tell us about your application, material, or failure mechanism and we will have one of our experts reach out to you. Our extensive library of research and years of experience gives us a unique advantage to apply a finite element analysis to help diagnose the best application for your situation.