Need a More Custom Solution?

We guarantee that the Procudo® Laser Peening System can provide protection against corrosion, cracking, and many other types of metal fatigue. It’s a turnkey solution, adaptable to many standard applications.

Still, not all parts fit a standard mold due to complex geometry, hard-to-reach stress locations, or size. And you may not be able to easily move or manipulate an outsize component.

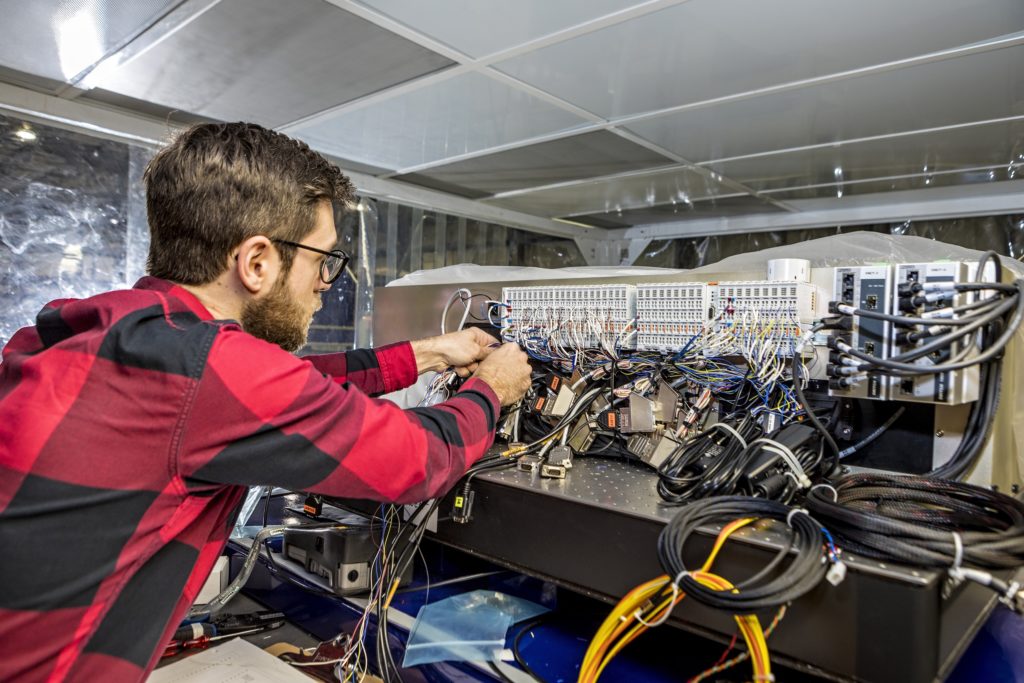

So let’s move the conversation toward ways to use the Procudo® Laser Peening System in ways that can include custom tooling or technology to meet your application with precision.