Applications of Laser-Induced Stress Waves

Discussing future laser systems and appropriate parameters for laser shock peening applications

Posted: May 23, 1978

By:

Originally presented at Lasers In Modern Industry Seminar, May 23-24, 1978.

Authored by B. P. Fairand and A. H. Clauer.

INTRODUCTION

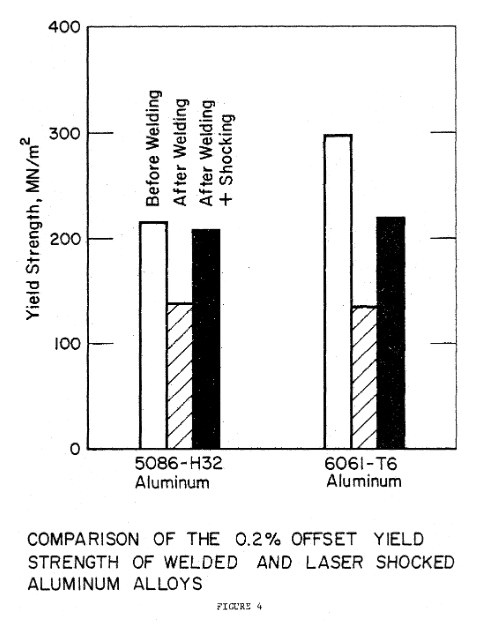

When light from a pulsed laser is incident on the surface of an absorbent material, part of the light is absorbed and vaporizes a small amount of surface material. The rapid vaporization and blowoff of this material generates a stress wave at the surface. As this pressure pulse propagates into the material, it changes the metal’s microstructure, which is the source of the observed improvements in material properties. This laser shock process has been successfully used to increase the strength and hardness of stainless steel. The strength properties of heat-affected zones in welded aluminum structures have been increased to values up to the strength of the parent material. Recent studies have demonstrated that laser shock processing can also be used to improve the fatigue life and stress corrosion of some aluminum alloys. In general, all alloys which are strain hardenable have a good chance of responding favorably to the laser shock process.

Active investigation of the effects of laser induced stress waves to materials began in our laboratories in 1971. Results of several years of research have led to a good understanding of the pressure environments generated by pulsed lasers and their effects to materials. Certain facets of this area of technology still require additional studies of a basic character. However sufficient knowledge has been gained from past research to realistically look at the use of laser induced stress waves for the solution of specific material related problems. This paper addresses materials problems presently under investigation and looks at other areas where laser stress waves have potential application. As a prelude to the discussion of laser applications, a review is given of the types of pressure environments generated by pulsed lasers. The application section is followed by a discussion of the types of present and future laser systems possessing appropriate parameters for shock processing applications.

To download the entire article as a pdf, go to Applications of Laser-Induced Stress Waves

Interested in Seeing More?

Tell us about your application, material, or failure mechanism and we will have one of our experts reach out to you. Our extensive library of research and years of experience gives us a unique advantage to apply a finite element analysis to help diagnose the best application for your situation.