LSP Technologies wins customers in new markets

LSP Technologies, Inc. (LSPT) is launching new applications for its patented Laser Peening Process to serve the nuclear power, heavy equipment, and aircraft maintenance industries.

Posted: July 30, 2018

By:

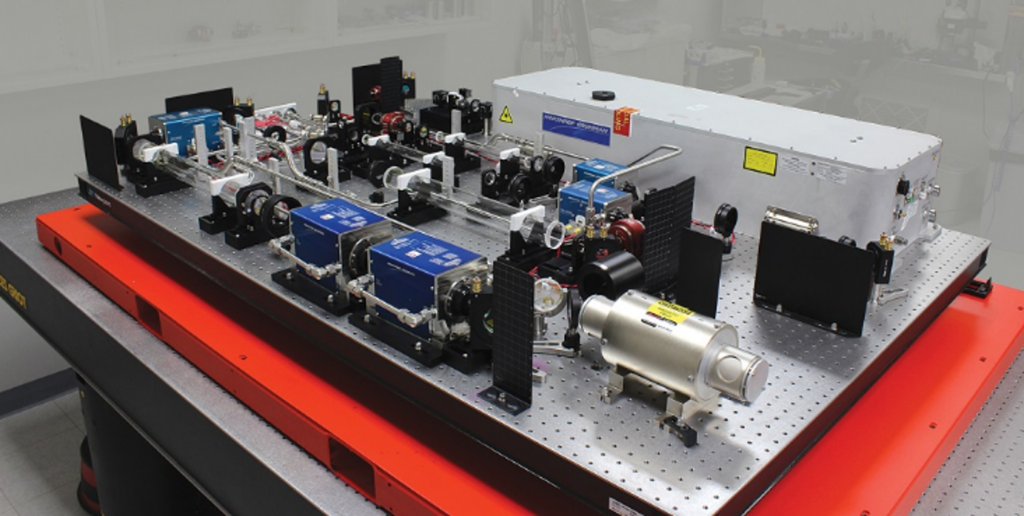

Precision, portability, and cost-effectiveness help open markets for the Procudo® Laser Peening System

New customers are adopting LSPT’s Procudo® Laser Peening Systems due to their precision, flexibility, low cost, and higher throughput rates, said President and CEO Jeff Dulaney.

LSPT’s patented Laser Peening Systems use a pulsed shock wave from high-energy lasers to enhance the ability of parts to resist foreign object damage (FOD), stress corrosion, and metal cracking.

“Our Laser Peening Systems increase the service life of many metal components by 10-20 times,” Dulaney said. LSPT’s metal stress modeling identifies stress points and enables precisely calibrated laser pulses for fatigue life improvement without damaging metal surfaces the way shot peening usually does, he said.

“The Procudo® Laser Peening System is the only commercially available laser peening equipment capable of a wide variety of customer applications,” he explained. “We can install the equipment in customer manufacturing and maintenance facilities.”

“On a part with a large flat area, the Procudo® Laser Peening System can run at full energy and at speeds of up to 200 hz. For parts with more complicated geometry, we fine-tune the relevant parameters to produce a precise peening pattern for metal enhancement and fatigue life improvement. ,” Dulaney said. “Shot peening and other surface processes cannot provide comparable results.”

Innovative LSPT solutions now in commercial development include:

• Portable laser peening equipment and fiber optic laser tool attachments to strengthen difficult-to-reach components for aircraft maintenance and other equipment, using pulse speeds up to 200 hz.

• Adapting Procudo® Laser Peening Systems with custom tooling to mitigate metal fatigue for nuclear power equipment, designed to boost fatigue life for a wide range of pipes, fuel storage casks, and reactor vessel heads.

• Automated laser peening of large crank shafts for the heavy equipment industry, utilizing robotic laser peening delivery and custom tooling.

LSPT holds more than 70 laser peening and related patents, and it is the first and only supplier of laser peening equipment to industry. LSPT can provide laser peening services from its Dublin, Ohio home facility, or provide equipment for customer work sites – both stationary units for factory production lines and portable laser peening equipment for maintenance and repair operations.

“This is a pivotal time for LSP Technologies. We now have Procudo® Laser Peening Systems in the U.S., Europe, and China. In addition to expanding in domestic markets, we can globally demonstrate the metal strengthening capabilities of our equipment, as well as collaborate with new customers on innovative applications for laser peening technology,” Dulaney said.

LSP Technologies is the world’s premier laser peening services, technology, and equipment provider. It is the only company in the world selling, installing, and integrating state-of-the-art laser peening systems into manufacturing, maintenance, and research facilities. The company has been providing laser peening production services for clients in the aviation and power generation industries for over twenty years and has been awarded more than fifty patents for innovations in laser peening equipment and technology.

Interested in Seeing More?

Tell us about your application, material, or failure mechanism and we will have one of our experts reach out to you. Our extensive library of research and years of experience gives us a unique advantage to apply a finite element analysis to help diagnose the best application for your situation.