Residual Stresses are Key to Metal Fatigue Improvement

Laser peening strengthens metal parts by producing compressive residual stresses within the material.

Posted: January 20, 2017

By:

Laser peening strengthens metal parts by producing compressive residual stresses within the material. The process is generally applied to part locations that are susceptible to fatigue failure, stress corrosion cracking, foreign object damage, or other types of metal failure. The residual stresses created by laser peening provide significant strength enhancement to failure-prone areas, making metal parts more durable and reliable with longer service lifetimes.

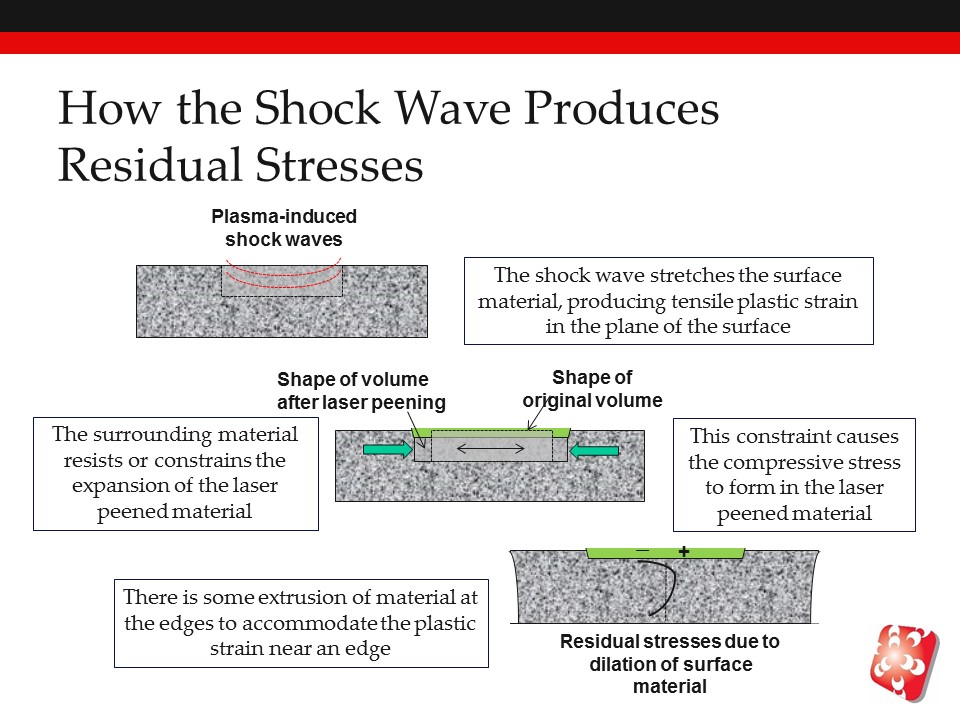

The image below provides some illustration of how compressive stresses are produced by the laser peening shock wave.

As the laser-produced shock wave propagates into the part, it induces a plastic strain along the plane of the part’s surface. Plastic strain causes the part’s surface to stretch – as seen in the middle image above – resulting in a corresponding resistance from the surrounding material as it pushes back against the expansion. This constraint generates compressive stresses in the laser peened area.

Compressive stresses enhance component life by inhibiting the initiation and propagation of fatigue cracks. Deep compressive residual stress profiles provide increased robustness when subjected to tensile loads or high cycle fatigue environments. Laser peened material retains a compressive residual stress profile that extends up to ten times deeper than those achieved by shot peening.

LSP Technologies provides laser peening production services for metal fatigue enhancement. Contact us to learn more.

Interested in Seeing More?

Tell us about your application, material, or failure mechanism and we will have one of our experts reach out to you. Our extensive library of research and years of experience gives us a unique advantage to apply a finite element analysis to help diagnose the best application for your situation.