What Is Shot Peening?

A surface enhancement method for improving the fatigue strength of metals near the surface of the component, shot peening is performed by impacting part surfaces with spherical shot particles to induce compressive residual stresses.

Posted: March 5, 2020

By:

What is Shot Peening?

Shot peening is a cold-working process that imparts a layer of compressive residual stress in the surface of a metal part. Each shot particle acts as a small peening hammer, creating an indentation in the part surface and plastically deforming the material. As the metal compresses at the point of impact, the surrounding material is displaced laterally and the part surface retains a layer of compressive residual stress.

How Does Shot Peening Work?

Compressive stresses act as a counterbalance to the tensile surface stresses present in many metallic components, and they inhibit the initiation and propagation of fatigue cracks that occur under service loads. Shot peening extends the fatigue life of metal parts by enhancing their resistance to corrosion, erosion, stress corrosion cracking, foreign object damage and fretting fatigue, while work-hardening part surfaces to enhance their resistance to wear.

Peening Measurement Parameters

Shot peening is controlled via two key parameters: Intensity and Coverage.

Intensity is a measure of the energy imparted by shot peening, and is dependent upon factors like hardness of the shot media, shot media flow rate, and angle of impact. Peening intensity is measured using Almen test strips – small steel coupons of uniform dimensions which are peened prior to part processing to calibrate compressive residual stress profiles.

Coverage is the percentage of the surface impacted by shot media and is typically a function of time. Given the random distribution of shot media impacts across a surface, shot peening is often applied in overlapping passes to ensure uniform distribution.

Shot Peening Methods

There are several popular methods for delivering shot media to the target workpiece:

Wheel Blasting – Blast wheels utilize rapidly spinning paddles to propel shot media via centrifugal force. Wheel blast machines can deliver high volumes of shot media at high velocities, and are typically used for peening large, flat surfaces.

Air Blasting – Air blast systems propel shot media using a stream of high-pressure air. The shot particles are accelerated through a nozzle, providing more precise application than wheel blast systems. Some systems incorporate water or liquid lubricants into the blast stream to enhance the surface finish of the target workpiece.

Flapper Peening – Rotary flap peening is performed using rubberized fabric flaps with embedded shot media attached to a rotating shaft. As the shaft spins rapidly, the flaps repeatedly impact the target – peening the material with constrained shot media. Flapper peening is a controlled method typically applied to small areas or repaired parts.

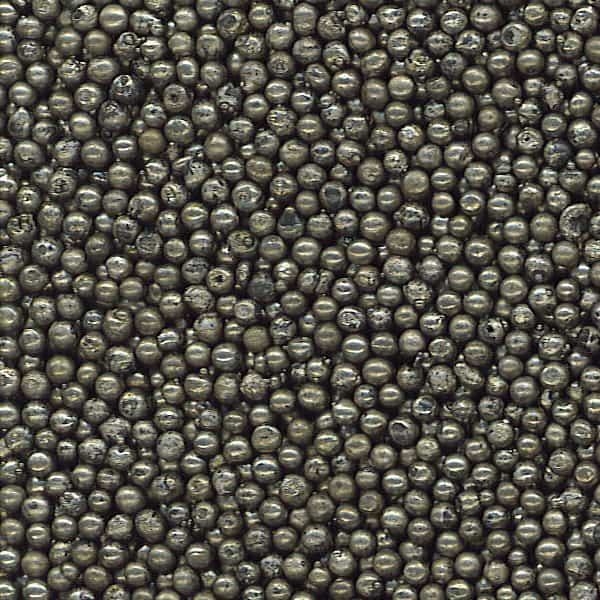

Shot Peening Media & Particles

Shot media is typically 1/8th of an inch or less in diameter, and is rated by size, shape, hardness, density, and durability. Effective peening requires shot media of consistent shape and hardness, so shot particles are often sorted and separated using mechanical shakers to remove nonconforming pieces. Some shot material can be reused for multiple treatments, but all shot media will eventually degrade and fracture over time.

Image Source

Shot media is selected based on the material characteristics and geometry of the part being treated. Metallic shot media may be composed of copper, steel, aluminum or other alloys, but shot media must be at least as hard as the workpiece to induce plastic deformation.

Common types of shot media include:

- Cast Steel Shot

- Glass Bead Shot

- Ceramic Bead Shot

- Cut Wire Shot

While shot peening remains a popular surface enhancement method, fatigue strength improvements are proportional to the magnitude and depth of induced compressive residual stresses in a treated component. Laser peening has proven to impart compressive residual stresses up to ten times deeper than those achieved with shot peening, and laser peening has demonstrated service life extensions superior to any other fatigue enhancement method.

Contact us to discuss the comparisons between shot peening and laser peening.

Interested in Seeing More?

Tell us about your application, material, or failure mechanism and we will have one of our experts reach out to you. Our extensive library of research and years of experience gives us a unique advantage to apply a finite element analysis to help diagnose the best application for your situation.