Laser Shock Peening: A Metal Fatigue Solution for All Metals and Alloys

Laser Shock Peening (LSP) is a universal metal fatigue solution for enhancing all metals and alloys.

Posted: March 30, 2018

By:

Precision Component Enhancement

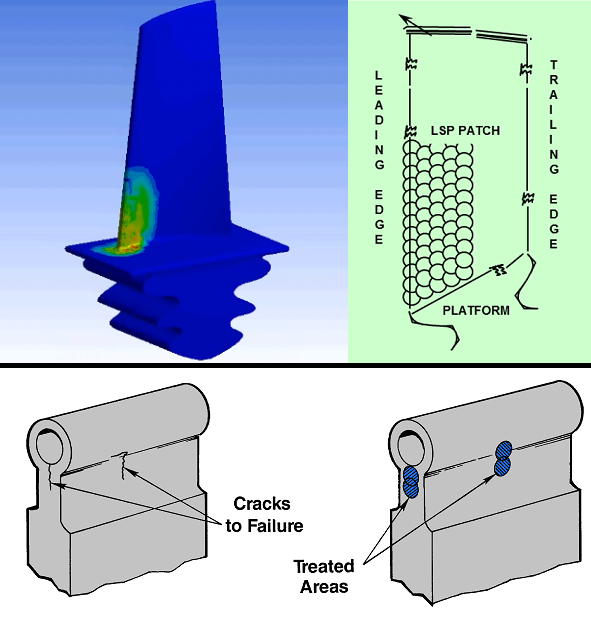

Laser Shock Peening (LSP) is a universal metal fatigue solution for enhancing all metals and alloys. LSP generates powerful shock waves that produce a tailored field of deep compressive residual stress. This robust compressive layer inhibits cracking beneath the surface, extending component lifetimes 10X or more.

Laser peening is a precise, strategic enhancement process that is customized for each unique component. Laser peening is applied to select locations on the part surface to impede cracking and improve fatigue performance.

There is no “one-size-fits-all” laser peening treatment, but LSP is so versatile and effective that nearly all components will benefit from a tailored laser peening application. This versatility derives from the unique recipe developed for each application.

A Unique Recipe for Fatigue Enhancement

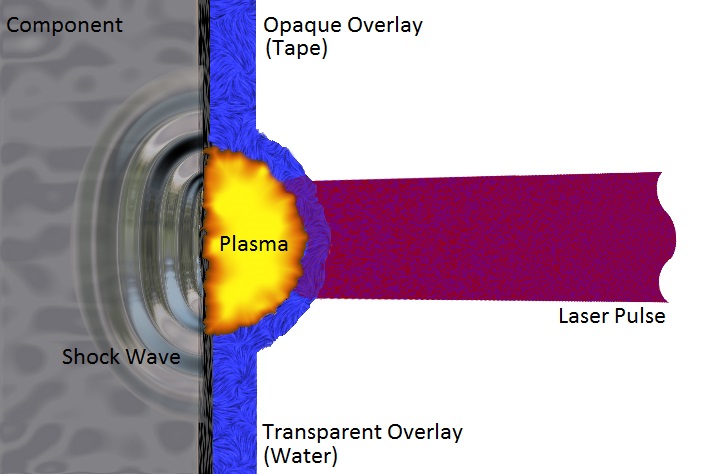

LSP delivers a succession of laser pulses to the component surface, with each pulse producing a high-pressure plasma burst. The expanding plasma shocks the surface and sends powerful compressive shock wave deep into the part.

The mechanics of the shockwave and resultant material effects are tailored by manipulating fundamental characteristics of the laser beam like energy, spot size, and pulse duration. These elements correlate to the pulse power density, which is a measure of power per unit area – a critical value which can be scaled up and down based on the target material and desired result.

Softer metals like aluminum are typically peened with a power density in the range of 3-5 GW/cm2. Harder metals like titanium and steel are processed at power densities of 10 GW/cm2 or greater. The following chart shows residual stress profiles for laser peened titanium with increasing power densities:

This value is easily optimized for each laser peening application. Raising the pulse energy or shrinking the spot area will both result in higher power density, higher plasma pressure, and a more powerful compressive shockwave.

A Universal Fatigue Solution

Laser Peening is renowned for its power, depth, and versatility. It’s a custom metal fatigue solution that can be optimized to prevent cracking in any part made of any metal.

Whatever your material, whatever your fatigue problem, whatever your operating environment – LSP Technologies has a laser peening solution to meet your needs.

Find Your Fatigue Solution

Interested in Seeing More?

Tell us about your application, material, or failure mechanism and we will have one of our experts reach out to you. Our extensive library of research and years of experience gives us a unique advantage to apply a finite element analysis to help diagnose the best application for your situation.