- We examine the characteristics of your part closely, tailoring our work to your part’s alloy, thickness, and shape

- Failure issues are pinpointed (corrosion, cracking, FOD, fretting, etc.)

- We determine critical fatigue locations and establish proper treatment pattern and depth

- You receive your custom quote based on your component and a solution that meets your requirements and budget

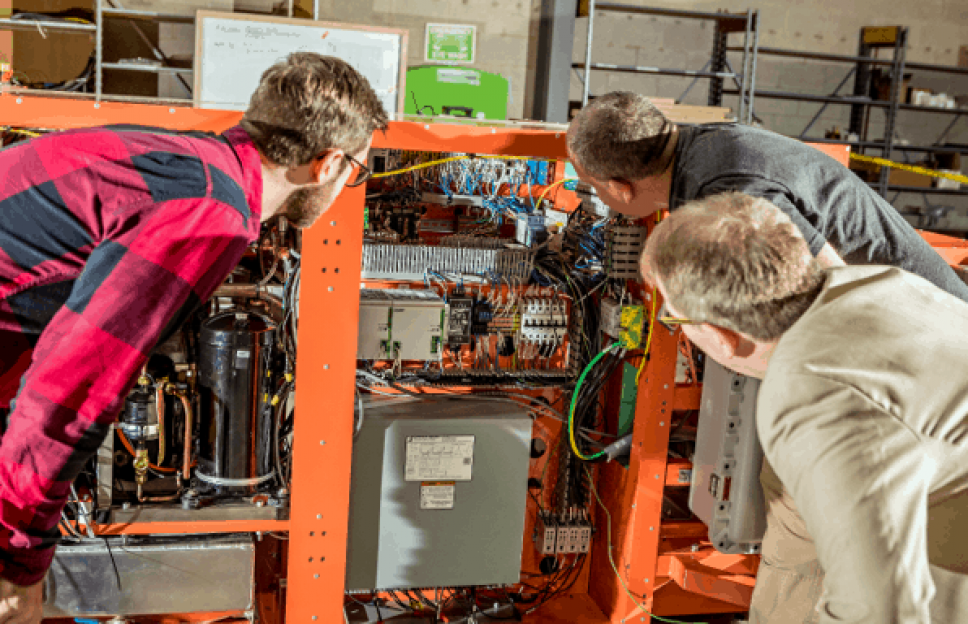

Application Development at LSP Technologies

Enhancing the Safety and Reliability of Your Components

Start The Application Development ProcessOur team analyzes your components, their purpose, and their operating conditions. Using an extensive library of research and past applications, we begin to put together a plan on how laser peening can meet your requirements.

Take a look at our laser peening application development process below

The Laser Peening Application Development Process

A 5-step overview of how our team engineers the ultimate solution to defend against metal failure.

- 1. Develop Quote

- 2. Experience and Modeling

- 3. Design Your Laser Peening Solution

- 4. Sample Testing

- 5. Production Planning or Custom Solution

- Pinpoint components stresses that contribute cracking, corrosion, and fatigue failure

- Apply our in-depth library of laser peening processes to your part’s alloy, thickness, and shape

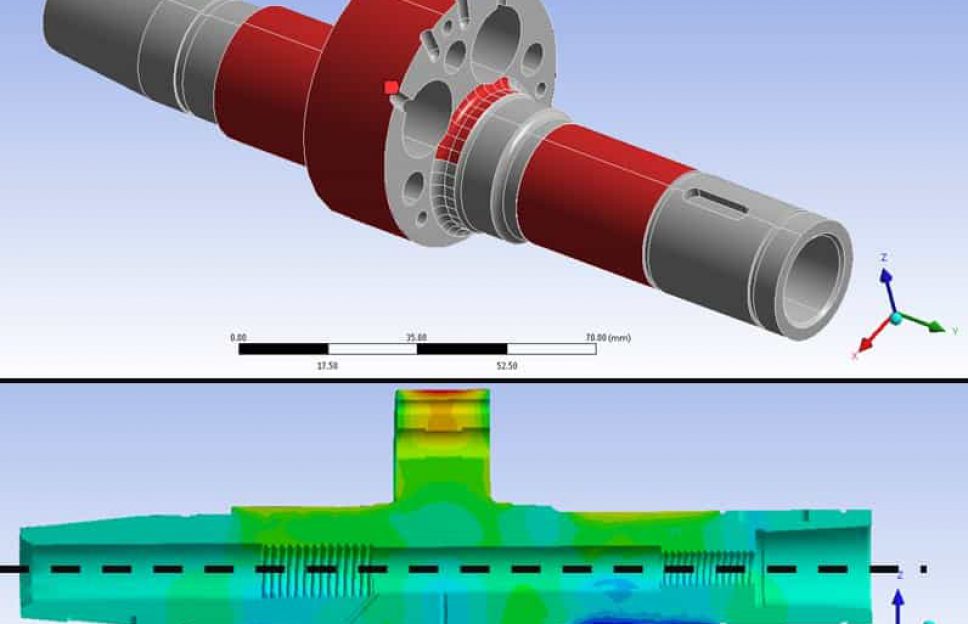

- We simulate part operations and hazards with Finite Element Analysis (FEA) modeling

- Pinpoint precise surface areas for laser peening

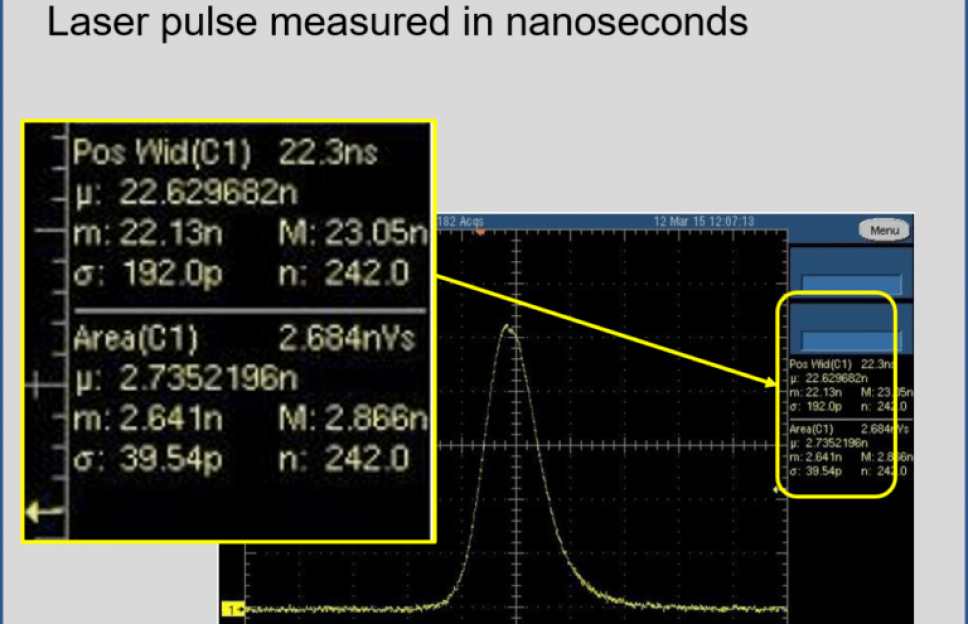

- Adjust parameters of proper laser energy, pulse width, and beam size

- Prescribe a laser peening pattern to produce the life-extending benefits you require

- Baseline fatigue strength life is measured for the existing part

- We apply an engineering laser peening solution to a representative coupon part or selection of parts

- Treated parts are examined in our in-house materials testing lab, an external lab, or your testing lab for verification

- We use laser peening depth and residual stress patterns to estimate life extension – as much as 10 times the usual life of untreated parts

- Together, we develop a production or custom plan and set of quality standards to guarantee performance results for your part

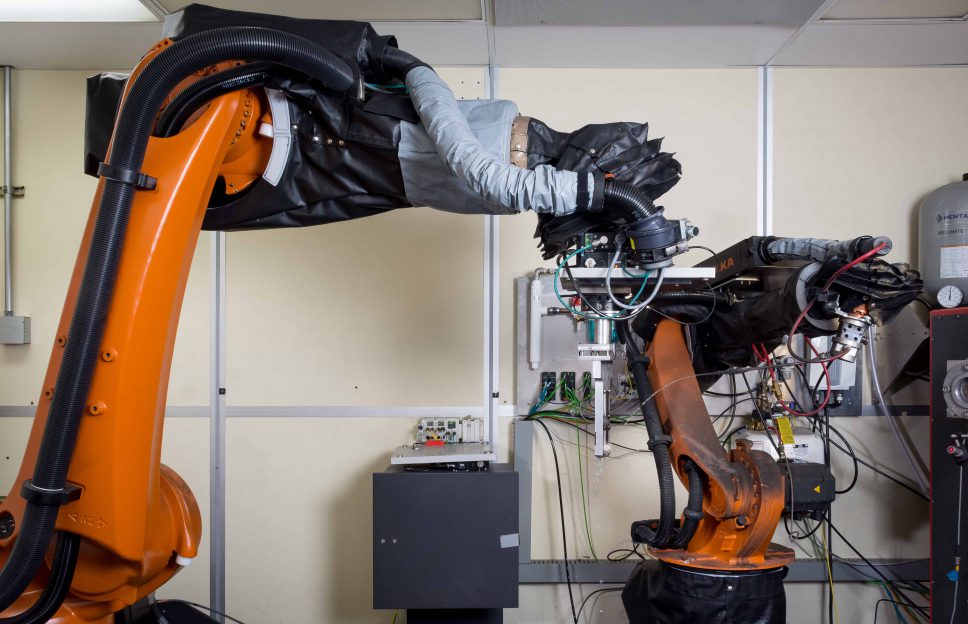

- We can provide laser peening services at the LSP Technologies, Inc. HQ in Dublin, Ohio

- Or, we can install a complete laser peening system at your facilities using our equipment

Controlled Laser Peening Parameters

Our materials experts analyze, model, and design the most optimal surface treatment for each part. See how:

Ready to get the Application Development Process Started?

Let’s start the discussion today. Let us know what your component is, it’s operating environment, and specified requirements and our team will get started right away with determining the best course of action towards success.

We look forward to understanding and assessing your needs to design the best laser peening solution possible.