Laser Peening For Aerospace

Metal Component Improvements For Mission-Critical Parts In the Sky

Our laser peening process protects critical aircraft components from damage, cracking, fatigue, and failure. We’ve demonstrated the ability to improve component performance, reduce cost, and cut down maintenance time for the aerospace industry.

Aerospace Applications

Laser peening has been a crucial technology to improve the safety and reliability for a variety of aerospace components.

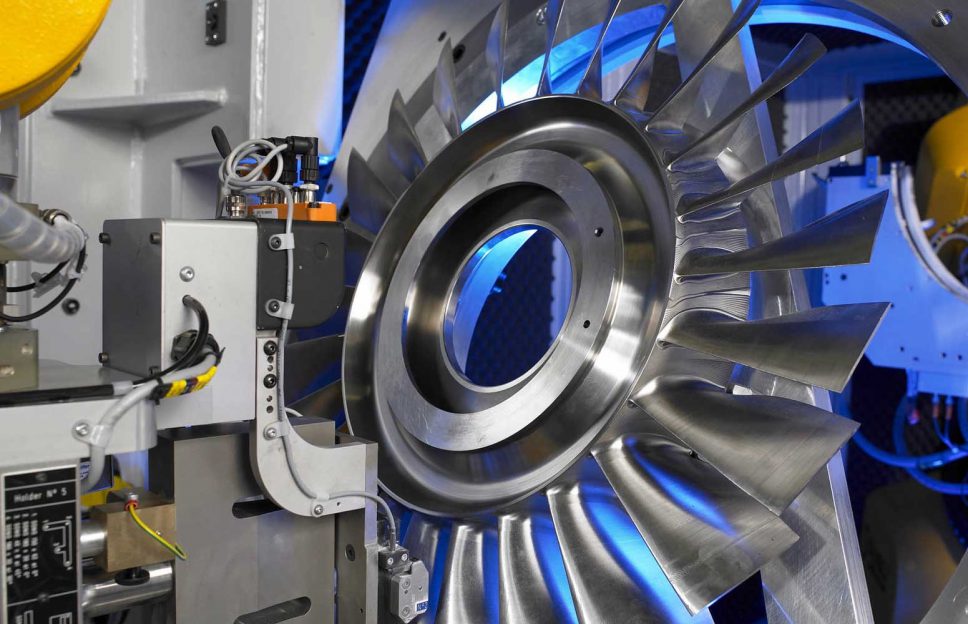

- Engine Components

- Turbine, Fan, and Compressor Blades

- Bulkheads

- Wing Attachments

- Flight Control Mechanisms

- Wheels

- Brakes and Landing Gears

- Welded Titanium and Aluminum Components

- Fasteners and Fastener Holes

- Welded Aging Parts

Laser peening can demonstrate material improvements in a variety of metals including: titanium alloys, steel alloys, stainless steels, nickel alloys, aluminum alloys, carburized and nitrided steels.

Don’t see your application?

Contact Us

Advantages of Laser Peening in Aerospace

Why would you consider using laser peening? Because it’s being used today to improve the safety and reliability for components in an industry that is counted on everyday for commercial, residential, and government use. Laser peening provides a trusted solution unmatched by common technology.

- Up to 10x Component Life Improvement

- Prevents Costly Failures

- Precisely Controlled and Localized Process

- Decreases Downtime

- Enables the Design of Lighter Weight Components

- Reaches a Depth 10x Deeper Than Other Surface Enhancement Technologies

Take a Look at Some Real-World Examples of the Impact of Laser Peening

Let’s Get Started

We guarantee that laser peening can provide protection against corrosion, cracking, and many other types of metal fatigue.

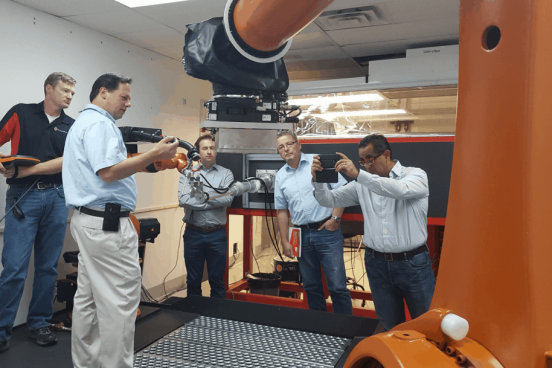

We begin by understanding your parts, their purpose, and operating conditions.

Then we use computer modeling, as well as our extensive library of industry applications to show how laser peening can meet your needs.

Let us show you how laser peening can extend the operating life of your part by 3-10 times.