Shot Peening vs. Laser Peening

Discover the Superior Solution

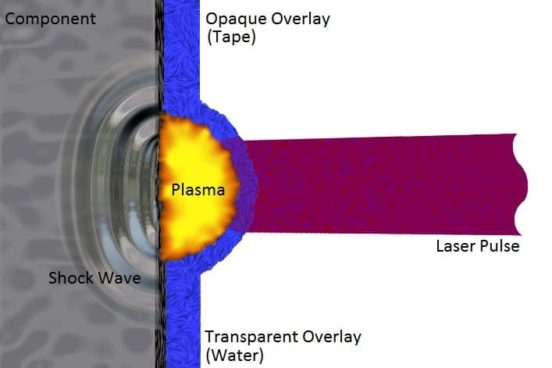

Make The Switch To Laser PeeningLaser shock peening emerged as a necessary application for parts requiring greater fatigue enhancement than shot peening and other technologies could provide.

What is Shot Peening?

Shot peening is a cold work, surface modification process aimed to improve the fatigue life of metal components through inducing compressive residual stresses. It is used when components experience metal failure due to high-cycle operating conditions.

Shot peening is commonly seen in the aerospace, automotive, heavy machinery, and power generation industries.

What is the Process of Shot Peening?

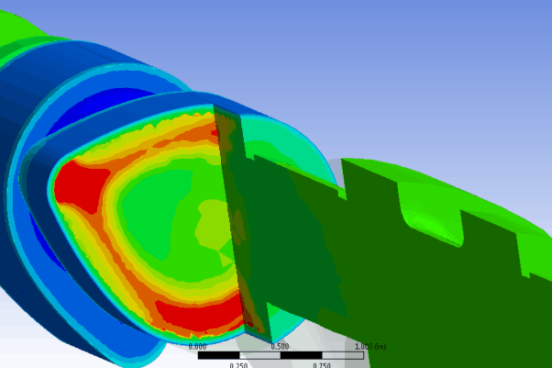

The process of shot peening involves accelerating a steel shot or other hard media (metal, ceramics, glass) toward a component’s metal surface at high velocities. The impact of the media with the metal surface causes a plastic deformation which changes the mechanical properties of the surface. The mechanical change of the metal surface produces compressive residual stresses and crack initiation is prevented or slowed down.

Does Shot Peening Improve Fatigue Life?

When the shot hits the surface of a metal part, an indentation is created which generates the beneficial compressive residual stress. Once the residual stress is induced, the surface is more resistant to cracking and failure because tensile stresses are removed.

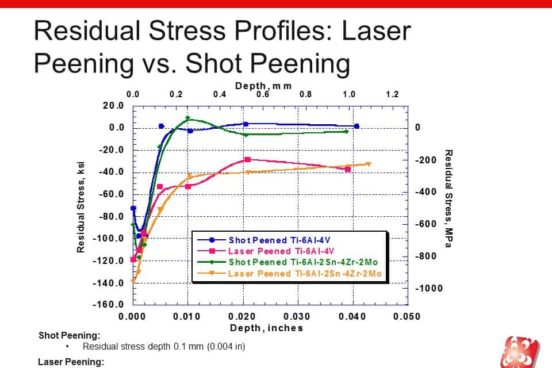

Fatigue improvement is often determined by parameters like density, material, size, hardness, geometry, distance, and angles. Shot peening fatigue improvement is best implemented in metal parts that require compressive residual stresses at shallow depths.

SO WHY LASER PEENING OVER SHOT PEENING?

Advantages of Laser Peening

Why would you consider using laser peening? Because it’s being used today to improve the safety and reliability for components in industries that are counted on for commercial, residential, and government use.

Laser peening provides a trusted solution unmatched by common technology. Laser peening has impoved the fatigue strength in a wide-range of metals including titanium alloys, stainless steel, aluminum alloys, and nickel alloys. The short laser pulse provides precision, depth, and power to areas of components that experience high fatigue.

Laser peening has been shown to provide over 10x life increases for components that had previously only been shot peened. This type of service life extension is unparalleled among surface enhancements, and has the power to revolutionize many industry practices. Not only will laser peened parts last longer, but they can be manufactured with less material to reduce costs and improve efficiency.

Beyond enhanced fatigue resistance and service life, laser peening has proven superior to shot peening across a number of performance-related applications:

- Retains compressive residual stresses to higher temperatures

- Reducing crack growth rates (da/dN)

- Improving life of welded components

- Improved fretting damage resistance

- Improved galling resistance

- Improved spallation resistance

- Improved stress corrosion (SCC) resistance

Laser peening consistently outperforms shot peening when it comes to the material enhancement properties associated with compressive residual stresses.

Other Surface Enhancement Technologies

The Laser Peening Difference

See real-world examples of how laser peening outperforms other surface enhancement technologies, like shot peening.

Laser Peening is the Superior Solution

When other technologies aren’t cutting it, it’s time time to consider the leading technology for metal surface enhancement. Laser peening has a proven reliability when it comes to providing fatigue cracking resistance. Our technology is being called upon across a variety of industries due to the unmatched compressive residual stress profiles.

The potential cost savings and benefits of increasing component lifetimes extend far beyond the value of the part itself.

Let’s talk about implementing laser peening into your process.